Wholesale Transmission Parts – Transmission Supply Shop

Wholesale Transmission Parts

Transparts Warehouse is a premier online transmission supply shop that offers wholesale transmission parts for standard and automatic transmissions, transfer case parts, and transmission coolers to shops and consumers alike. We offer only the highest quality standard and automatic transmissions, performance transmission rebuild kits, transmission shift kits, performance transmission parts, and accessories.

Whether you want to rebuild a standard or automatic transmission yourself or run a transmission repair shop, Transparts Warehouse carries the parts and transmission master rebuild kits you need to get the job done on time and on budget. With many years of experience running and operating our own small transmission shop, we know the importance of getting your hands on affordably priced wholesale transmission parts in a hurry.

Make Transparts Warehouse your online transmission supply shop today.

Transmission Parts- Mister Transmission

Transmission parts knowledge for people researching how transmissions work.

A transmission is an impressive puzzle to most drivers, made up of many intricate connections among a multitude of transmission parts. The complexity of these parts and how they fit together is intimidating, especially if you’re facing transmission repairs and you don’t understand what’s happening or why.

While we need to trust our transmission mechanics to take care of the specifics, knowing a little bit about the transmission parts that might be malfunctioning can help to set your mind at ease during the transmission repair process.

The first step to a basic understanding of transmission parts is to understand the purpose of the transmission as a whole. Your automatic transmission is responsible for transferring the power of your engine to the drive shaft and wheels so that your car can move within its optimal range of revolutions per minute (RPM). The transmission maintains this optimal range by shifting transmission gears as you drive faster or slower.

The main transmission parts that need to work together are:

Planetary Gear Sets

Hydraulic System

Torque Converter

Computer

Planetary Gear Sets

Manual transmissions use a clutch to connect the engine and transmission. They require the driver to shift the transmission gears, which means actually moving the gears in a somewhat linear, sliding transfer to engage with the coordinating gears needed to maintain the proper RPM ratio. Automatic transmissions keep the transmission gears in one place, in a more circular structure. This is not unlike a small solar system, hence the name Planetary Gear Sets.

Using the combination of an outer ring gear, a central “sun” gear, and two or more smaller “planet” gears, which are all constantly meshed together, the transmission takes over the gear shifting from the driver. Much like the solar system, the sun gear is in the centre and remains stationary and the smaller planet gears engage with it and the ring gear to keep the car moving smoothly.

The ring gear is connected to the input shaft, which brings power from the engine. The planet gears exist within a casing or carrier that is connected to the output shaft which carries power to the drive train and wheels. The planet gears are also connected to a clutch pack. The sun gear is connected to a drum, which is connected to the other half of the clutch pack.

Transmission clutch packs are a series of disks, half with splines on the outside edge, and half with splines on the inside edge. These alternating disks are made to fit together to lock and turn together. They do this using hydraulic functionality.

Hydraulic System

All of the transmission parts are constantly submersed in transmission fluid. This fluid is manipulated to create pressure, which pushes the transmission clutch pack together at the right time. A complex system of tubes moves the fluid around the transmission and torque converter to create this pressure. The transmission hydraulic system has three main purposes: to help control transmission gear shifting, to lubricate the transmission parts to prevent friction damage, and to keep the transmission cool. The fluid pressure within the transmission must be maintained at all times to prevent damage.

The tubes that transfer the transmission fluid have two major external seals at the front and back. The seal at the front protects the connection with the torque converter and the rear seal contains the fluid where the transmission meets the output shaft. Seals are made of neoprene. Within the transmission exists another type of seal, called a gasket, which connects and protects two stationary transmission parts. Gaskets may be made of any of a variety of materials, such as rubber or silicone. Seals and gaskets can harden over time, which might cause leaks and a drop in transmission fluid pressure, both of which can lead to damage to the transmission.

Torque Converter

When driving a manual transmission, the driver must engage the clutch or shift into neutral when the vehicle comes to a stop, such as at a red light, or the engine will stall. The torque converter in an automatic transmission allows the engine to continue running when the vehicle is stopped yet still in gear. Torque is defined as a force that causes rotation. The torque converter uses the pressure of the transmission fluid to control the rotation of its parts. When you are stopped at that red light, one half of the torque converter is turning while the other is stationary. When you accelerate, the fluid pressure forces the other half to spin in conjunction with the first half so that vehicle moves forward.

Computer

In most cars today, a computer controls the transmission’s function allowing all vehicle systems to work together for optimum fuel economy and power. As many as 30 sensors read all of the various factors such as vehicle speed, engine temperature, engine speed, etc, that control transmission gear shifting to ensure the optimal shift points are used.

The many transmission parts in your vehicle may remain a puzzle, but understanding some of the basics can help you to have a more informed conversation with your transmission mechanics before leaving it in their capable hands.

As Gene Lewis at the Moncton Mister Transmission says,

“We’re the specialists, transmissions are all we do.”

If you are experiencing a problem with your vehicle’s transmission, please contact your local Mister Transmission and book an appointment for our FREE 21-Point Multi-Check Inspection.

For a more in-depth explanation, please visit our Transmission School

Automatic Transmission Parts And Functions (Diagram Included)

How many parts are in an automatic transmission and what are their functions? Here is the ultimate guide to automatic transmissions, including a diagram.

While the engine is making all the power necessary to move your car the transmission put that power (transmits) to the car’s wheels and makes it move.

Engineers love to make things as simple, or more accurately said, as convenient as possible for the users of their product. The automatic transmission is far from simple but extremely convenient.

An automatic transmission consists of many precisely engineered parts that all have their respective functions.

In this article, we will go through the most significant parts, such as the torque converter, planetary gears, brake bands, clutches, and more.

All the functions of the respective parts will also be explained concisely and understandably.

The focus will mostly be on the hydraulic automatic transmission, which is the most common one.

Gear up and find out everything about automatic transmissions below!

Related:Bad Transmission Signs And SymptomsHow Much Does A Transmission Rebuild Cost?15 Essential Car Maintenance Tips

Table of ContentsShow

Why Is A Transmission Needed?

Before we dig into the exact details and the parts an automatic transmission consists of it is important to notice that an automatic transmission is incredibly complex.

Matter of fact, it even makes rocket science look like a walk in the park, and here is why:

The automatic transmission does not only consist of mechanical parts that rotate and transfer power from the engine to the wheels. It uses fluid, gears, pumps, and much more.

If it would only consist of a shaft, there would not be a need for transmission at all, as the engine could do the job perfectly.

The transmission, however, makes it possible to keep the engine running even when the wheels are stationary. If it did not, the engine would stall due to many reasons.

On the other hand, when the car must accelerate, the power output of the engine must be controlled and carefully applied.

Without a transmission, the engine’s RPMs would directly transfer to the wheels, making them spin incredibly fast and not grip anywhere.

The gears are there to multiply or divide the torque, making it possible to drive 85mph with a higher gear but the same engine speed as if you drove the car at 20mph in a lower gear.

In a manual, the driver manually changes the gears, which are directly linked with the gear stick. In the case of an automatic transmission, it is much more complicated as a planetary gearset is used.

Parts Of An Automatic Transmission

The automatic transmission consists of hundreds of parts if we were to be picky. Most of those parts make up a few general components that make the automatic transmission work smoothly.

These components (or parts) include a torque converter, planetary gears, brake bands, clutch plates, and output shaft, each of which is described in this article.

Due to the complexity, an automatic transmission is very expensive to rebuild.

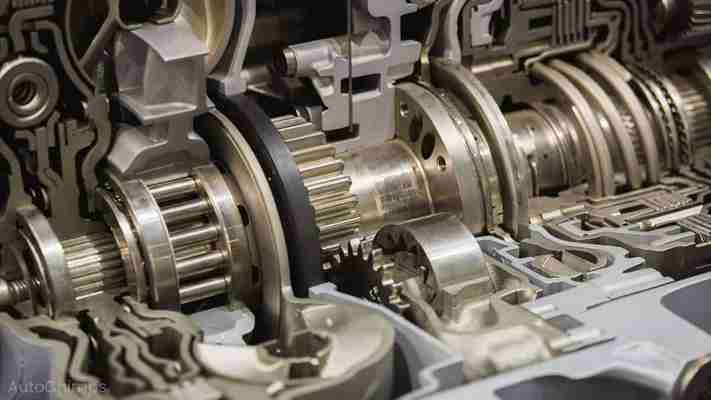

An automatic transmission diagram helps demonstrate the shared complexity of the engineering but illustrates the parts of the transmission very well.

Automatic car transmission

The most important parts are described in from the torque converter, located closes to the engine, to the output shaft which transfers the output of the transmission.

Torque Converter

The torque converter is an art in itself. Put it simply, it consists of four parts:

Impeller (also called pump) Turbine Stator (also called reactor) Lock-up clutch

The easiest part is to name them, as all these mechanisms are impressively engineered.

Together they make up the torque converter, which is analogous to the mechanical clutch of a manual transmission.

In other words, it is the link between the engine output and the rest of the transmission.

The torque converter works with the help of mechanisms dependent on transmission fluid.

To best understand the mechanism, it is best to cover each part of the torque converter separately, there is a lot of engineering involved, but we will make sure to keep it as simple as possible.

The Impeller (Pump)

The impeller is connected to the crankshaft via the flywheel which rotates the impeller. This in turn means that it rotates at the same speed as the crankshaft.

As the impeller rotates, the fluid in the torque converter gets “pumped” towards the turbine, between these two components, the stator is located, which we will cover shortly.

Keep in mind that the impeller is directly related to the engine output and propels the automatic transmission fluid to transfer the energy. It is not mechanically connected to the turbine.

Turbine

Turbine of an automatic transmission

The turbine is on the other end of the torque converter, which means it is the “receiver” of the fluid pumped by the impeller and then connects directly to the transmission’s input shaft.

As previously mentioned, it is not connected to the impeller, which is directly affected by the engine output.

This means that the speed of the turbine, which affects and is affected by the wheel speed, is independent of the impeller, and therefore the engine speed.

This is crucial for keeping the engine going even when the wheels are stationary. If this mechanism would not exist, the car would stall.

Stator (Reactor)

The stator lies in between the turbine and the impeller and the turbine. It is responsible for “torque converting” and is not always engaged.

The stator’s engagement is dependent on the speed of the turbine, or more precisely the speed of the fluid from the turbine. This is key in its torque converting capability.

It does not stop there though, the stator is also responsible for sending the transmission fluid back to the turbine, making somewhat of a closed-loop system.

So how does the stator convert the torque and how does it work?

The stator is connected to a shaft, which in turn is connected to the transmission. It will only go in one direction, the same direction as the turbine.

Due to the design of the stator and fluid dynamics, the stator will only engage (start rotating) when the impeller reaches a certain (higher) speed.

Both the impeller and the turbine are similar to propellers with many long blades. As the impeller rotates it will push the fluid through the stator, which will propel it further to the turbine.

The stator can only rotate in the same direction as the impeller and turbine, thanks to a one-way clutch.

Furthermore, the stator is designed so that when the transmission fluid is propelled less “violently”, the stator, which does not move will direct the fluid to the upper ends of the turbine’s “blades”.

This, due to fancy physics increases the torque output by increasing the pressure. Lo and behold, the torque has been converted and increased!

The amplified torque is needed especially when the car starts to move. In that case, the stator is static.

When the turbine reaches a higher speed, the turbulent flow will get another “angle of attack”, pressing down the blades of the stator, and making it spin.

Due to the activation of the stator, the fluid in the torque converter will be less turbulent, hitting the turbine more to the center and therefore mitigating the torque amplification.

If it sounds a bit complicated, don’t worry, it is.

To get a better understanding, check out this YouTube video, which illustrates the torque converter mechanism well.

Lock-Up Clutch

The fourth substantial part of the torque converter is the lock-up clutch.

As the automatic transmission fluid plays a key role in the torque converter, it also poses a problem when greater speeds are evident, there is a loss of energy due to fluid mechanics.

This loss of energy makes the impeller and turbine spin at slightly different speeds which is not optimal when the car is moving relatively fast (around 35mph).

To combat this issue, the lock-up clutch engages and locks the turbine with the impeller, mitigating any loss of energy that would otherwise be present.

Planetary Gears

Both manual and automatic transmissions use gears to dictate how much torque should be sent to the wheels.

In a manual transmission, the gears are mechanically moved by the operator with the help of a gearshift, which is connected to a shift fork and lastly to the gears.

In an automatic transmission, things are much more complicated. Imagine the gears on a bike, but with different types of gears surrounding the standard ones, which engage “independently”.

This setup enables the transmission to automatically change gears with the help of brake bands and clutches (which is mentioned further down in the article).

To simplify this complicated part of an automatic transmission, we will keep it short and sweet.

Three types of gears constitute the automatic transmission:

Sun gear – located in the center of the whole gear system. Planet gear – located between the sun gear and the ring gear, multiple planet gears are present in the system. Ring gear – the outermost gear in the system.

Refer to the image below to see the three types of gears:

These three types of gears enable different amounts of torque to be finally delivered to the wheels, just like the gears in a bicycle.

All these different gears provide different rotational speeds depending on which gear is engaged, at what speed, and even the direction.

The gears are engaged with the help of bands and clutches.

Brake Bands & Clutches

The bands and clutches are important parts of an automatic transmission. They work in different ways but are both needed to properly engage or disengage a gear.

So, what do the bands in an automatic transmission do? To put it simply, the bands halt the clutches that are engaged, which is necessary for the gear selection and output.

The bands are powered by hydraulic fluid pumped by the torque converted. When needed, a sensor will engage the hydraulic pressure and the band will then connect and prevent a planetary gear to spin.

The clutches are also powered by hydraulic fluid. They consist of several clutch plates that come together when engaged and may then, for example, make a planetary gear move.

The best way to visualize this is through a diagram.

The video below shows how the planetary gear set works together with the clutch plates. A word of caution is that it is extremely complex.

Output Shaft

All the things previously mentioned, from the impeller in the torque converter to the planetary gears helped by brake bands and clutches all have one goal – get the energy to the output shaft.

The output shaft is what makes your wheels rotate and consequently make the car move.

Is An Automatic Transmission Complicated?

Yes, an automatic transmission is complicated. Nevertheless, is it a great feat of engineering that makes the driving of many people much easier.

There are many other parts that we have not touched such as bearings, sensors, oil reservoir, and many others transmission parts.

Either way, we hope you have a greater understanding of how an automatic transmission works.